Glass International News

-

15 years of Forglass Bucket Elevators Development

“In all we do, we believe our clients need safety, reliability and technological progress” says Piotr Knast, Forglass CEO.

17 April 2024 -

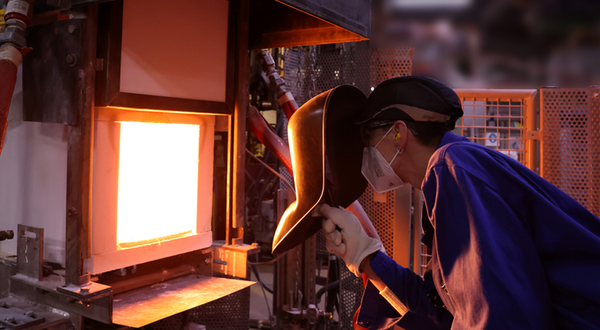

Hrastnik1860 conducts hydrogen furnace trials with Sorg

Hrastnik1860 and Sorg will conduct an industrial-scale trial to heat a glass melting furnace with hydrogen.

15 April 2024 -

O-I Glass in vegetable oil transportation plan

O-I Glass is set to reduce its CO2 emissions in the UK by using vegetable oil to transport its spirits bottles.

12 April 2024 -

Rath achieves record financial results

Refractories manufacturer Rath achieved record financial results in 2023, despite difficult conditions.

12 April 2024 -

Cristalerías Chile forecasts increased glass production in 2024

Glass manufacturer Cristalerías Chile has forecast a stronger 2024 after an increase in sales in the first quarter of the year.

11 April 2024 -

Glassman in Mexico: FAMA introduces remote monitoring service

FAMA will introduce its remote monitoring service, an advanced solution that tracks production processes 24/7.

10 April 2024