Speciality glass group Schott is manufacturing a 39-metre primary mirror (M-1) for the European Large Telescope (ELT) at its production facility in Mainz, Germany.

Schott, which specialise in speciality glass and glass ceramics, are constructing glass-ceramic called Zerodur. The melting team are casting the first mirror segments, which will be completed in 2024.

Marc Cayrel, from the European Southern Observatory’s (ESO) project team, said: “Casting the mirror substrates for the M1 is a milestone in ESO’s project plan.

The telescope's main mirror will be humanity’s largest eye on the sky, enabling us to reach unprecedented depths of space.”

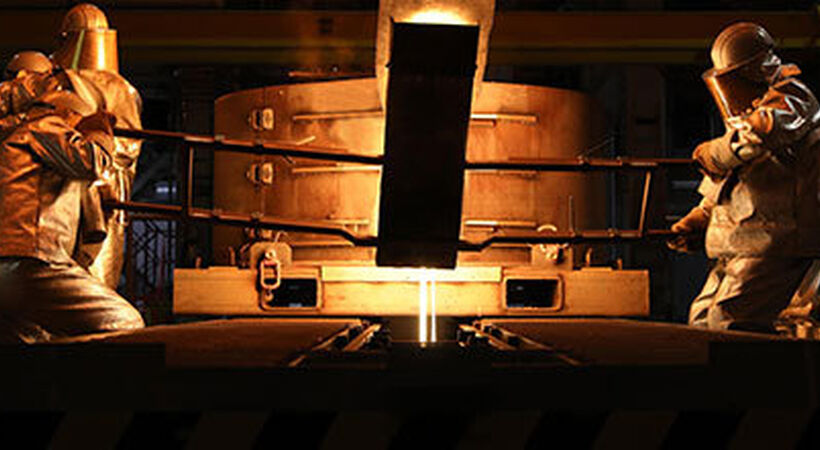

In order to construct the segments, liquid glass is heated to more than 1400°C and will be poured directly into moulds. It will then be transferred into a cooling furnace and subjected to a ceramicisation process lasting several weeks.

Dr Thomas Westerhoff, Director of Strategic Marketing for Zerodur at Schott Advanced Optics, said: “The glass consumption factor will be as low as possible, so we can work more efficiently.

Thanks to significant expansion of production capacity at the Mainz site, Schott is well prepared for the production of Zerodur glass-ceramic, both for the ELT project and for the demand from the high-tech industry.”

The Zerodur blocks will be cut into five slices of approximately 60-70 mm in thickness. A computer-controlled 5-axis CNC machine will complete any further processing. French company Safran Reosc will polish off the final M1 segments. The giant mirror will include a total of 798 segments.

The ELT will also include a convex mirror (M2) of 4.2 metres in diametre, a concave mirror (M3) of 3.8 metres in diameter and an adaptive mirror (M4) of 2.4 metres in diameter.

Due to high demand, two glass-melting tanks are in parallel operation. As a result, new jobs were created for around 50 employees and additional capacity-enhancing investments are planned for the coming year.