Polish technology company Forglass has launched a furnace that can simultaneously melt two or more different types of glass.

Merging the need to quickly implement changes in production schedule involving different glasses with the desire to maintain the highest possible melting efficiency for as long as possible in one furnace is difficult, often impossible.

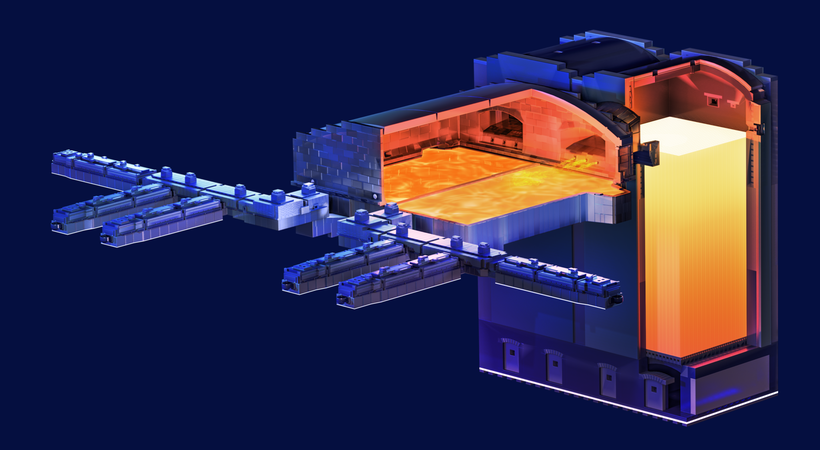

The Forglass MultiGlass furnace is the answer to these expectations because it can simultaneously produce smaller volumes of two or even several glasses with energy consumption comparable to melting only one glass in a standard, single-tank furnace.

Lower energy consumption per ton of glass also reduces the emission of environmentally harmful compounds (CO2, NOX, SOX), and eliminates reject of glass that is unsellable due to its undesired properties or quality, but has to be produced when changing the glass composition in the furnace ‘on-the-fly’.

The Forglass MultiGlass furnace is the ideal option for both greenfield investments and modernisations in restricted spaces.

For many glassworks located in urban areas, this opens up new opportunities for expansion or restructuring of their production capacities.

Conversion of a standard furnace into the Forglass MultiGlass furnace can be carried out in any glassworks by expanding the furnace (adding a second tank) only in its width, not length.

It is generally the only space available in the production hall and, what’s crucial, the expansion of a U-fired furnace does not involve radical rebuilding of the regenerator, which makes it inexpensive and fast.